New Breakthrough in Pipe Pile Applications in Southeast Asia: First Engineering Pile Projects in Thailand and the Philippines Successfully Constructed

Release time:2025.05.14

Page View:1552

New Breakthrough in Pipe Pile Applications in Southeast Asia: First Engineering Pile Projects in Thailand and the Philippines Successfully Constructed

Through solid market research, product promotion, and international trade channel development, with a focus on key markets in core regions, the application of pipe piles in Thailand and the Philippines achieved a breakthrough from scratch in Q2 2025, marking a significant step forward in the company's internationalization strategy.

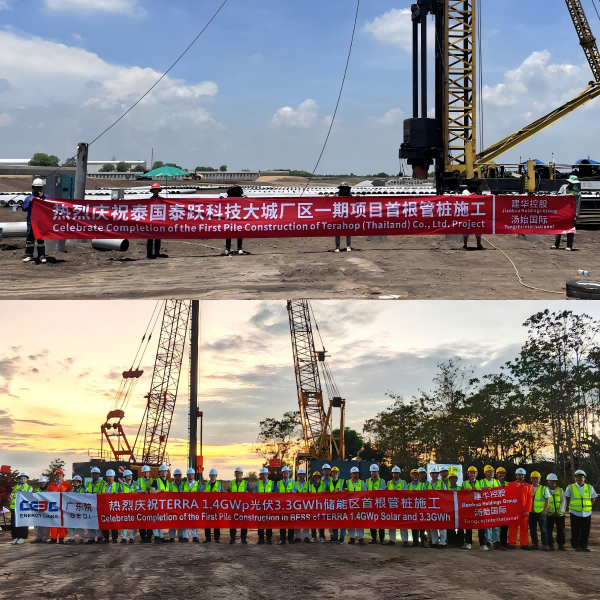

Thailand Industrial Plant Project

This project represents the first successful application of high-strength pipe piles in Thailand. The project's geological survey report indicated predominantly medium-hard to hard low-plasticity clay, where high-strength pipe piles offer significant advantages. However, the original geological report only included bearing capacity values for local I-beam piles and precast square piles, and there was no prior precedent for high-strength pipe pile applications in Thailand, leading to concerns among the owner, design institute, and general contractor.

Through thorough demonstration and discussions with the client, the original plan using 450 precast square piles (C40 concrete strength) was optimized to PHC500 national standard pipe piles. This reduced the number of pile positions by 30% and the volume of pile caps by 20%, significantly saving costs for the owner while shortening the construction period. After pile testing, the single-pile bearing capacity fully met design requirements. Large-scale construction of engineering piles is currently underway, and the successful application of this project will provide a strong case study for promoting high-strength pipe piles in the Thai market.

Philippines Photovoltaic Energy Storage Project

As the largest photovoltaic-energy storage integrated power plant in Southeast Asia, this project has a total investment of over US$600 million and covers an area of 3,500 hectares. Upon completion, it will supply power to approximately 2.4 million households.

For the geological conditions in the energy storage box area, the original design used bored piles, which had issues such as high costs and long construction periods. Through full communication with the design institute, our company proposed replacing bored piles with PHC-400 pipe piles, reducing the pile length from the original 14 meters to 10 meters. After successful pile testing, we invited the owner (Philippines National Grid), supervision company, and design institute to conduct on-site inspections and experiments at our facility, gradually alleviating their concerns about pipe pile applications and designating Jianhua pipe piles as the sole supplier for the Philippines National Grid.

By optimizing pile layout and reducing the usage of pile caps, the project ultimately saved approximately 25% in costs, shortened the construction period from the original planned 120 days to 45 days, and avoided on-site mud pollution, aligning with local environmental requirements in the Philippines. This has laid a solid foundation for the subsequent entry of pipe pile products into the Philippine photovoltaic sector.

By optimizing pile layout and reducing the usage of pile caps, the project ultimately saved approximately 25% in costs, shortened the construction period from the original planned 120 days to 45 days, and avoided on-site mud pollution, aligning with local environmental requirements in the Philippines. This has laid a solid foundation for the subsequent entry of pipe pile products into the Philippine photovoltaic sector.

Return

Return